Key Points/Overview

Polycarbonate plastic made with BPA is shatter-resistant, lightweight, and has high optical clarity, similar to glass. Epoxy resins made with BPA are tough and readily adhere to metal surfaces, making them excellent materials for protective coatings.

BPA is one of the most thoroughly tested chemicals in use today and has a safety track record of more than 50 years.

Scientific studies show that in humans BPA is quickly metabolized and eliminated from the body.

Learn more about BPA at FactsAboutBPA.

What is BPA?

BPA is one of the most thoroughly tested chemicals in use today and has a safety track record of more than 50 years. The consensus of major government agencies around the world is that BPA is safe as used in food-contact applications. The CLARITY Study, a 5+ year, multipronged U.S. federal government research program and the largest study ever done on BPA, confirms BPA’s safety. The results, released in 2018 by the U.S. National Toxicology Program, were accompanied by a statement from Dr. Stephen Ostroff, Deputy Commissioner for Foods and Veterinary Medicine at the U. S. Food and Drug Administration (FDA), saying: “our initial review supports our determination that currently authorized uses of BPA continue to be safe for consumers.”

You may have heard claims that BPA exposure causes health effects in people. Scientific research shows that in humans, BPA is quickly metabolized and eliminated from the body – it does not accumulate in blood or tissues. Because of the way BPA is processed in the body, it is very unlikely that exposure to BPA at typical levels could cause health effects.

This is further confirmed by CLARITY, as “the results clearly show that BPA has very little potential to cause health effects, even when people are exposed to it throughout their lives,” said Steven G. Hentges, Ph.D., Polycarbonate/BPA Global Group of the American Chemistry Council (ACC).

Uses & Benefits

Products made from BPA meet high-performance demands. Epoxy resins made with BPA are tough and readily adhere to metal surfaces, making them excellent materials for protective coatings. Polycarbonate plastic made with BPA is shatter-resistant, lightweight, and has high optical clarity similar to glass.

Polycarbonate Plastic

- Strong, shatter-resistant polycarbonate is used for helmets and protective sports visors to help protect children and athletes from injuries.

- Polycarbonate plastic also is used to make housings for electronic products such as cell phones and laptops, as well as optical discs such as CDs and DVDs. Because of its extreme durability and strength, polycarbonate plastic is particularly useful for making component parts that need to be thin and light, but strong.

- Polycarbonate plastic used in automobiles helps make cars lighter and more fuel-efficient while maintaining safety.

- Polycarbonate plastic provides the benefit of long-lasting transparency and durability in new, design-inspired LED lighting in vehicles.

Epoxy Resins

- Food cans and other metal containers may be coated with epoxy resin linings made with BPA to help prevent direct food contact with metal, which helps protect food from contamination and spoilage.

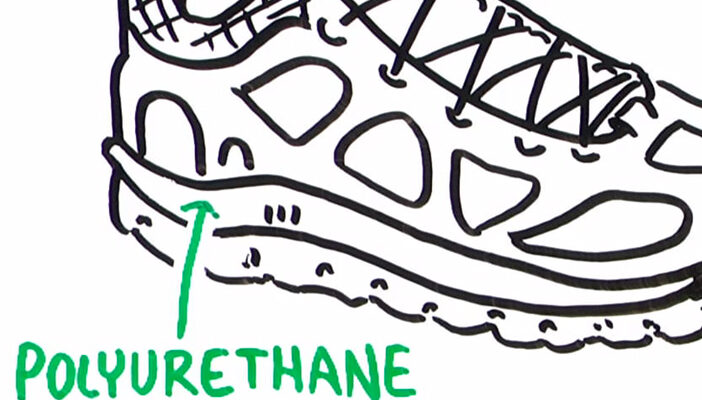

- High-performance epoxy resins are used to make aircraft, cars, bicycles, boats, golf clubs, skis and snowboards durable, flexible and strong.

- Durable and decorative floorings, such as terrazzo flooring, chip flooring and colored aggregate flooring, are made from epoxy resins.

Safety Information

The results of the CLARITY Study, a 5+ year, multipronged U.S. federal government research program and the largest study ever done on BPA, confirm BPA’s safety. Released in 2018 by the U.S. National Toxicology Program, the data supports FDA’s one word answer to the question “Is BPA safe?”: “Yes”. It is important to note that scientific experts at FDA, and other regulatory bodies, review the full weight of the scientific evidence when making decisions about safety.

Government agencies that have evaluated the safety of BPA include:

- S. Food and Drug Administration (February 2018)

- Food Standards Australia New Zealand (February 2018)

- South Korean Ministry of Food and Safety(March 2016)

- German Federal Institute for Risk Assessment (February 2015)

- Food Standards Australia New Zealand (January 2015)

- Health Canada (September 2012)

- Swiss Federal Council (December 2011)

- Japanese National Institute of Advanced Industrial Science and Technology (July 2011)